Change Language :

iglidur® - pv value and lubrication

Table 01: Thermal conductivity of shaft and housing materials

| Material | Thermal conductivity [W/m x k] |

|---|---|

| Steel | 46 |

| Aluminium | 204 |

| Grey cast iron | 58 |

| 304 stainless steel | 16 |

| Ceramics | 1.4 |

| Polymer | 0.24 |

pv value

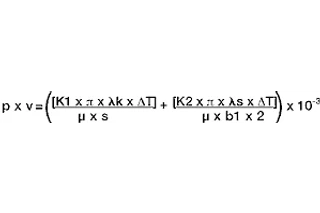

The product of the specific load [p] and the surface speed [v] is of particular importance for plain bearings. The pv value can be regarded as a measure of frictional heat and therefore be used as an analytical tool to check a plain bearing's suitability. For this purpose, the actual pv value is compared with a predictable permitted pv value. The permitted pv value depends on the shaft material, the ambient temperature and the duty cycle.

permitted pv value:

| In these equations: | |

|---|---|

| K1, K2 | Constant for heat dissipation (K1 = 0.5, K2 = 0.042) |

| Øs | Bearing wall thickness, mm |

| b1 | Bearing length [mm] |

| μ | Coefficient of friction |

| λs | Thermal conductivity of the shaft |

| λk | Thermal conductivity of the bearing |

| ΔT | (Ta - Tu) |

| Tu | Ambient temperature |

| Ta | Max. Application temperature |

Correction factor

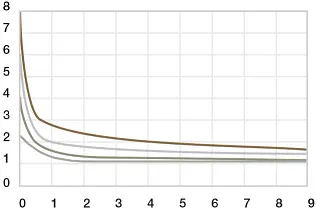

The permitted pv value can be increased in intermittent operation if the bearing temperature does not reach the maximum at all due to the short run time. Tests have shown that this is the case with run times below 10 minutes. The shorter the run time, the lower the maximum bearing temperature reached.

An important factor here is the ratio of duty cycle and pauses. It is obvious that long pauses contribute more to re-cooling. The different curves in Diagram 09 represent the different ratios (three times means that the pause lasts three times longer than the run time).

Correction factor of the permitted pv value due to intermittent operation

X-axis: correction factor

Y-axis: duty cycle [min]

| Lubrication | Correction factor |

|---|---|

| Dry operation | 1 |

| During installation | 1.3 |

| Continuous, grease | 2 |

| Continuous, water | 4 |

| Continuous, oil | 5 |

Lubrication

Although iglidur® plain bearings are designed for dry operation, they are compatible with standard oils and greases. One-time lubrication during the installation improves the start-up behaviour and the coefficient of friction, thus reducing frictional heat. Due to this effect, the permitted loads for plain bearings can be increased by lubrication. Numerous results from lubricated applications are available from tests. Please contact us if required. Table 03 shows the correction factor for the pv value when lubricants are used.

Consulting

I look forward to answering your questions

OEM Finland OY+358 207499499Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 17 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr