Change Language :

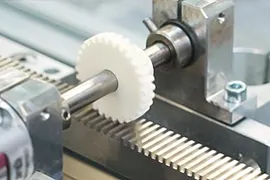

Wear-resistant 3D printing plastics for components in moving applications

Our 3D printing materials are up to 50 times more abrasion-resistant than conventional plastic. This makes them the ideal material wherever components come into contact with movement. On this page you can find out which materials fulfil special requirements such as, e.g. food conformity or ESD suitability.

In our shop you will find detailed technical information and processing instructions for all our 3D printing materials. Material profiles are also available for download for easy processing of our filaments on standard 3D printers from Bambu Lab, Prusa and Ultimaker. ⯈ To the material shop

What do iglidur plastics have in common?

All iglidur materials contain the same basic materials developed specifically for plain bearings. This means that they are all self-lubricating and wear-resistant thanks to integrated solid lubricants. You can find more details on the specifications of the iglidur base materials in the plain bearing wiki.

All-rounder materials

The iglidur 3D printing materials are all-rounders that can be used for any type of wear application under normal conditions.

The bestsellers here are the laser sintering powder iglidur i3 and the tribofilament iglidur i150.

If, on the other hand, an all-rounder material with significantly higher flexural strength and/or temperature resistance is required, iglidur i230 is the right material for your application.

Heat-resistant materials

This category includes 3D printing materials that can withstand a permanent application temperature of at least 120°C (without deforming): For such higher application temperatures, we offer wear-resistant tribofilaments and laser sintering powders.

What needs to be considered when processing heat-resistant tribofilaments?

- To process high-temperature filaments, you need a 3D printer with a build chamber temperature of at least 160°C.

- It is particularly important to store the high-temperature filaments protected from moisture and to dry them before use in order to avoid undesirable quality problems.

Materials that are suitable for ESD

Food-safe materials

Our 3D printing materials also include some with food conformity for safe use in the food and packaging industry. Food conformity guarantees that materials that come into contact with food have been tested for the level of transferred plastic components. EU Regulation 10/2011 and the FDA in the USA stipulate limit values for this, above which the material is no longer food-safe. The permitted contact time also plays a role and varies depending on the FDA or EU 10/2011 declaration of conformity and ambient temperature.

Tips for 3D printing with food-safe tribofilaments:

- Protect food-compliant filament from dust

- Thoroughly clean all contact parts before printing, especially the extruder pinion, print nozzle and print bed

- Do not use any adhesive or use food-grade adhesive

- Select slicing software settings for a dense surface

- Reduce the printing speed and adjust the line width to the nozzle diameter

Materials for structural components and multi-material printing

DLP and LCD resin

The iglidur 3D printing resins particularly stand out from conventional resins due to their enormous wear resistance and maximum strength.

Thanks to the integrated solid lubricants, they are self-lubricating and are particularly suitable for the production of wear-resistant parts with the finest details.

Like the other igus 3D printing materials, the resins are also processed to order in the in-house 3D printing service. They are also available as a material in the shop and can be processed on DLP and LCD 3D printers.

Tips and print profiles for filament 3D printing

3D printing tips

No more stringing, warping and spaghetti - with our 24 tips you can easily avoid common problems with filament printing.

Download here

Filament printing profiles

For optimum processing of the igus filaments, we offer the material profiles for selected printer models for download.

Learn moreIn-house material test laboratory and printing service

Tested!

3D printing materials made of iglidur compared to PLA, ABS and other materials and manufacturing processes.

To the test results

3D printing service

Customised additively manufactured components in just a few steps with the online 3D printing service.

To the igus® 3D printing serviceConsulting

I look forward to answering your questions

OEM Finland OY+358 207499499Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 17 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr