Change Language :

Modular robotics

As individual as your needs – the modular assemblies from igus

igus specialises in developing robotics components made of durable, wear-resistant plastics. The basic idea of modular robotics is that various modules and components can be combined to create customised automation solutions. This enables companies to react flexibly to different requirements without the necessity of expensive, time-consuming new developments. Using low-cost components that still deliver high quality enables companies to implement automation solutions at lower costs. This can be especially attractive for small and medium-sized companies that want to automate their production processes, but have limited resources. Overall, the igus combination of modular design and Low Cost Automation offers the capability of creating tailor-made automation solutions for various industries. This not only promotes efficiency and productivity, but also contributes to manufacturing process modernisation.

Min. 1 million Life cycles

Over 1,000 tests per year

Over 10 years of experience

Assemblies as single components

Gearbox assembly

Modular concepts allow different types of gearboxes – planetary gearboxes, strain wave gears, worm gears, etc. – to be flexibly integrated into automation systems. The modular specifications of gearbox assemblies allow automation to be gradually expanded and adapted. Companies can add additional modules to improve their robotics systems' functionality without having to start from scratch. The modules offer precision, versatility, and adaptability in developing efficient automation systems that are cost-effective while remaining high-performance.

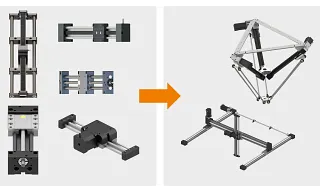

Linear guide assembly

Linear guide assemblies are modular, so different elements such as rails, carriages, and guide carriages can be combined to achieve the desired motion sequences. New modules can be added or replaced to meet the needs of different applications. This contributes to flexibility and enables companies to adapt and expand their automation solutions as needed without starting from scratch. They offer precision, flexibility, and cost-effectiveness to support companies as they develop and implement cost-effective, high-performance automation solutions.

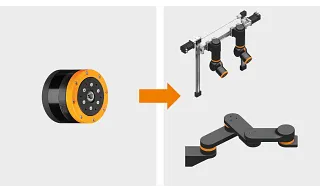

ReBeL strain wave gear

The ReBeL strain wave gear stands out thanks to its innovative design and versatility. It combines precision and robustness to ensure reliable motion control. New modules can be seamlessly integrated into existing systems to expand functionality or meet application requirements. This promotes agility and enables companies to respond to changing production needs. It offers precision, robustness and versatility to help companies develop cost-effective automation solutions that still deliver high performance and reliability.

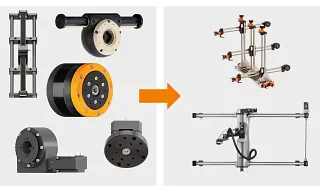

Apiro® gearbox modular system

The Apiro gearbox modular system is characterised by its versatility. It consists of various components such as gearboxes, drives, bearings and rails that can be combined with each other to achieve the desired motion guide. The modularity of the gearbox modular system enables companies to adapt and expand their automation solutions as required. New modules can be seamlessly integrated to add additional functions or respond to changing requirements. With its versatility, cost-efficiency and adaptability, it enables companies to develop innovative automation solutions that are both technically sophisticated and economically viable. Be inspired here.

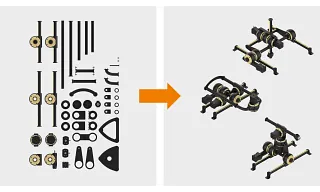

Apiro® starter kit

The Apiro starter kit is designed to help companies get started with automation. It consists of various components such as gearboxes, rails, bearings and drives that can be combined to create a wide range of motion solutions. This modularity allows companies to familiarise themselves with automation step by step and adapt their systems as needed. A particular advantage of the starter kit is its user-friendliness. It offers an integrated solution that allows companies to dive into the world of robotics without in-depth expertise.

Maximum freedom with assembly interoperability

Combine the individual assemblies as required

Assembly interoperability means that individual modules (robot arms, drive systems, grippers, or sensors) are designed to interact harmoniously. Standardised interfaces and communication protocols allow these assemblies to be developed independently, yet easily combined. This creates a modular system principle that enables companies to assemble specific robot solutions from different components. Quick reactions to market changes can thus be undertaken and new products introduced. Companies do not have to develop new robots from scratch every time, but can instead reuse existing assemblies. Overall, “maximum freedom through assembly interoperability” represents a turning point in modular robotics. This approach opens a world of possibilities for companies to tailor their automation solutions to their exact needs.

No minimum order quantity

Maintenance-free

Quick amortisation

igus robot control

The "igus Robot Control" is a modular robotics solution that enables companies to precisely control and customise their automated systems. With innovative features and user-friendly operation, the igus robot control helps optimise automation solutions and offers a range of benefits:

- Modularity

- Intuitive operation

- Free and licence-free software

From complete robot control with free software to individual motor controllers for building your own robot control system. The possibilities are endless. Contact us to find out more.

More about Low Cost Automation

Consulting

I look forward to answering your questions

OEM Finland OY+358 207499499Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 17 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr