Change Language :

Intelligent energy chains & smart cables

smart plastic innovations 2024 ...

... Experience all smart plastic innovations 2024 such as the contactless condition monitoring for roller chainsEC.IT or the OTA-capable i.Sense module right here:

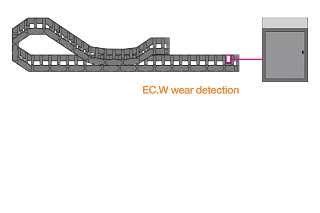

EC.W sensor for e-chain®

Sensor for abrasion on energy chain

- Measures wear on the crossbar, pin/bore connection or sliding foil, depending on the version

- Compares defined algorithms with the actual usage data

- Can also be used as a stand-alone sensor

"What should you consider when selecting e-chain® from a maintenance perspective?"

10 tips for a "maintenance-friendly" energy chain

This short guide provides numerous practical tips and tricks on what this means in concrete terms and what design engineers should consider.

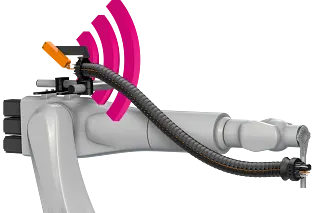

Smart e-chains®

Finally also for multi-axis & industrial robots ...

... i.Sense TR.B for intelligent breakage monitoring

Robots have long been an integral part of many areas of industrial production - whether welding, painting, soldering or palletising: Industrial robots work dynamically. A flexible multi-axis energy chain such as the triflex® R from igus® makes it possible to guide robot cables safely. In order to recognise potential chain breakages caused by the extreme load in good time and avoid unplanned machine downtime, igus® has developed i.Sense TR.B, the world's first breakage monitoring system for multi-axis energy chains.

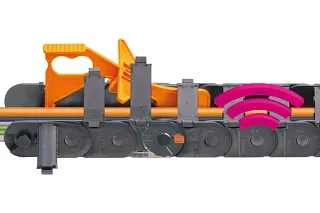

P4.1 Roller chain

- Longer service life thanks to maintenance-free tribopolymer plain bearings in the connection of the chain links

- For maximum stress and service life

- Travel distances of over 800 m at speeds of more than 5 m/s

- Always know how the chain is doing thanks to smart plastic

E4 chain series for the high load range

- sliding, unsupported, suspended use

- For robust, demanding applications

- inner height from 21 to 350mm

- Each chain link consists of 4 individual parts

- Can be opened in the inner and outer radius

E2 chains for the medium load range

- Internal heights: 26 to 48 mm

- Available in two versions:

- Hinged on both sides in the outer radius

- Hinged on both sides in the inner radius

- Improved weight and dimension ratio compared to the previous series

- Up to 55% faster to install than predecessors

3D CAD portal for smart plastics

Designing intelligent energy chain systems faster. CAD models for all smart components.

Our intelligent e-chain systems are already being used reliably in many hundreds of thousands of applications worldwide - from beverage vending machines and CNC machines to steelworks. Unsupported lengths can be bridged with ease and long travel distances are conceivable for a wide range of industries.

360° insight into the igus® test laboratory

All smart plastic test setups can be found here by rotating the mouse over the screen.

Smart solutions with chainflex® cable

No additional module is required for condition monitoring (i.Sense) using chainflex® cable.

The system can be operated without additional software during integration and networking.

In these cases, chainflex® cable takes over 3 possibilities of condition monitoring.

- Tensile and shear force measurement via the cable (CF.P)

- Measurement of the electrical specification of a cable (CF.Q)

- Measurement of the transmission quality (CF.D)

Sensors for chainflex® cable

Do you want to put together your own smart plastic package?

Then download the digital version of our smart plastic Domino now and put together your very own configuration.

You can then look forward to a playful gift from smart plastic.

Consulting

I look forward to answering your questions

OEM Finland OY+358 207499499Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 17 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr